Tube Filler and Sealer Manufacturer

Tube Filler and Sealer Manufacturer Application for Tube filling and sealing machine Full-automatic filling and sealing

Description

Basic Info

| Model NO. | TFS |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| Material | Ss3104/SS316 |

| Name | Tube Filling Sealing Machine |

| Application | for Aluminium Tube, Plastic Tube, Complex Tube |

| Tube Size | Customizable |

| Sealing Type | Copper Heating, Ultrasonic Sealing, Hot Wind Seal |

| Filling Products | Cream, Oil, Paste, Body Cream, Hand Cream |

| Cutter | Flat or Curve Cut |

| Transport Package | Wooden |

| Specification | 1070*1170*1950mm |

| Trademark | Welead |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 1000 Set Per Year Tube Filling Sealing Machine |

Product Description

Tube Filler and Sealer ManufacturerApplication for Tube filling and sealing machine

Full-automatic filling and sealing machine is a newly upgraded automatic filling and sealing machine developed by our company. It is suitable for precise metering filling and sealing of all kinds of plastic hoses and aluminium-plastic composite pipes. Using Taiwan technology cam divider and internal and external heating technology of copper block, it realizes a series of functions, such as automatic pipe release, automatic marking, high precision liquid filling, paste filling, uniform tail sealing, finished product delivery, etc. It is widely used in pharmaceutical, cosmetic, chemical, adhesive and food industries.

Machine Details

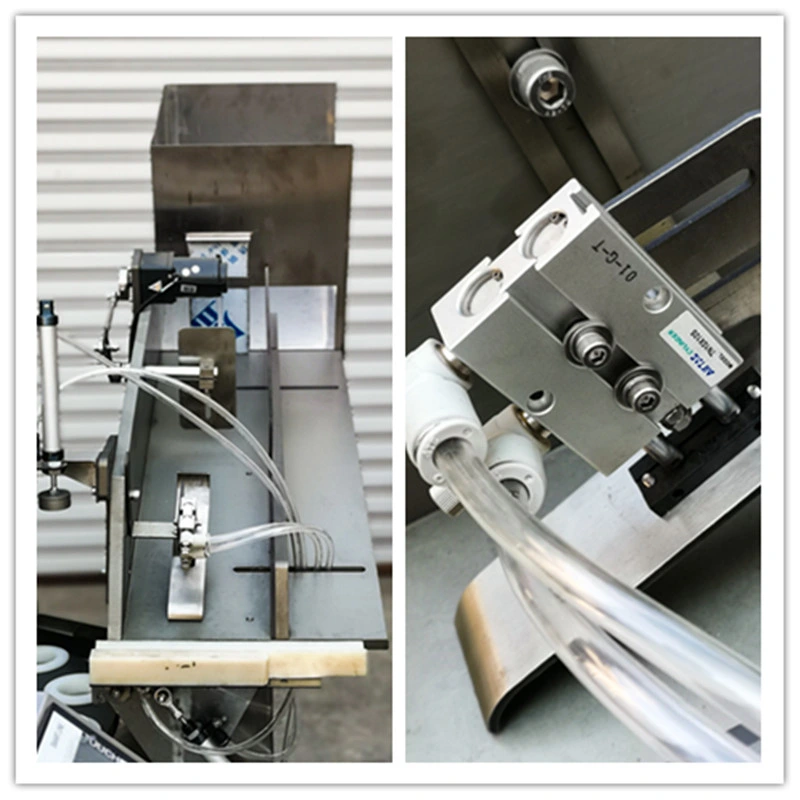

1. Automatic tube feeding convey

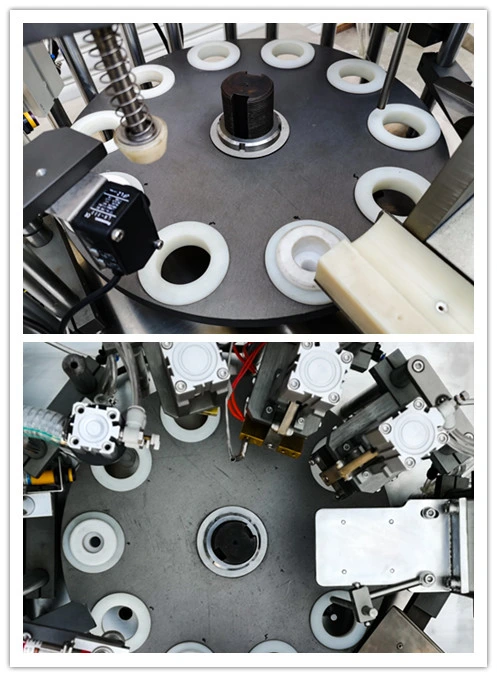

2. Turning Table

3. 25L Filling Hopper and FIlling Nozzle

4. Inner Heating & Outter Heating & Steel Letter Embossing

5. Panasonic Eyemark Sensor & Electronic Counter

6. Tube End Cutter & Cut Waste Convey

Factory Image

Performance and characteristic:

1. Reasonable design, simple operation, suitable for multiple sets of moulds, easy replacement.

2. Full-featured, versatile, suitable for all kinds of plastic pipe Aluminum-plastic pipe

3. Adopting PLC system to control the marking, the color marking detection is more accurate and the service life is long.

4. The material of the contact part with the material is 304 stainless steel, which meets the GMP standard.

5. The connection of each component is in the form of quick-loading, which is convenient for disassembly and cleaning.

6. Optional heat preservation mixing barrel for smooth filling of viscous liquid

7. Use high-quality pneumatic components to ensure more stable operation of the machine

Technical Parameter

| Power Supply | 220V 50HZ 1 phase |

| Filling Capacity (ml) | 2-50,10-100,15-150,20-200,25-250, customizable |

| Applicable Diameters (mm) | 13-44, 40-50 |

| Suitable Tube Height (mm) | 50-250 |

| Product Capacity (pcs/min) | 20-30 |

| Filling Accuracy | ±1% |

| Shape Size (mm) | 1100*800*1600 |

| Machine Weight (kg) | 450 |

| Working Pressure | > 0.4Mpa |

Company and Factory Image

Welead pharm company is a high-tech enterprise dedicated to the development and production of various pharmaceutical, food processing and packaging machinery, cosmetics and chemical industries. Our main products are related packaging and processing machinery such as tube filling and sealing machine, liquid filling machine, cream filling machine, eye drop filling machine, ampoul filling machine, and other solid machines like capsule filling machine, tablet machine, blister packaging machine, carton machine, counting machine. The company has passed SGS certification and our products have passed CE certification. We have high-quality staff and can provide you with good after-sales service. We have high-precision lathes and milling machines to provide you with quality machines. Most of our machines are exported to the United States, Spain, Germany, the United Kingdom, Canada, Malaysia, Thailand and other places, I hope that our machines can bring you more success!

Our Service

1. Pre-sales customer consultant service: to help clients to choose right and suitable model according their different products and requests, make quotations and provide professional suggestions and technical details.

2. Sales Service: to provide clients formal and legal contracts and right bank details, help clients to make order fluently, arrange the production according to clients request accurately and fast, keep checking production procedure, and inform clients the progress, provide clients with finished machine video or acceptance for clients' inspection visit, accompany clients to check the machines. Arrange shipment booking, prepare shipping documents, help clients to make clearance and release of shipment.

3. After Sale Service: to provide clients full set of brochure and installing video, help clients to get assistance from engineer.

4. Training Service: clients can send their technical person to our factory for training and inspection.

5. Oversea Installing Service: we can send our engineer to oversea to help clients install machines

6. Maintenance Service: All our machines can have life time maintenance with charges on local travel, distance guide online to help maintenance is for free all machine life.

Packaging and Delivery

Payment and Shipping

FAQ

Q1:Are you manufacturer or trading company?

A1: We are manufacturer with own factory and exporting department.

Q2: What's the lead time of your machine?

A2: Normally it's about 30~45 working days.

Q3: What's the payment terms?

A3: 30% deposit TT, 70% paid before shipment; or L/C, Western Union.

Q4: Can we check machine before order?

A4: Yes, welcome to visit our factory and check machine anytime.

Q5: Is it difficult to install the machine ?

Q5: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

Q6: Does the machine power voltage meet buyers' factory power source?

A6: We can do it as your request.

Prev: Small Type Easy Operate Semi Automatic LPG Refilled Equipment Snow Spray Aerosol Gas Filling Machine

Next: Zhitong Stainless Steel 314 / 306L Machine Plastic Tube Filler and Sealer for Ointment Cream

Our Contact

Send now