Semi Auto Aerosol Filling Crimping Machine/ Sunscreen Spray Filling Machine

Description

Basic Info

| Model NO. | QGBES |

| After-sales Service | Provide Spare Parts and Video Guidance |

| Warranty | 1 Year |

| Type | Volumetric Filling Machine |

| Automatic Grade | Semi-Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Air Cylinder |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Tank |

| Packaging Material | Metal |

| Condition | New |

| Certificate | ISO9001 |

| Brand Name | Meitar |

| After-Sales Service Provided | Engineers Avaliable to Service Machinery Overseas |

| No. | 2023051701 |

| Transport Package | Export-Worthy Package |

| Specification | CE |

| Trademark | Meitar |

| Origin | Jiangsu Yangzhou |

| HS Code | 8422303090 |

| Production Capacity | 120 Sets/Year |

Product Description

PLC Control Semi Automatic Bag on Valve BOV Aerosol Spray Can Filling MachineBOV Filling Machine, Widely Applied In:

Foods (Olive Oil),

PERSONAL CARE (Sun Screen Spray, Facial Mister Spray, Shaving gel/foam, Self-defense Spray, Pepper Spray, Disinfectant Spray),

HEALTH CARE (Nasal Spray),

OTHER INDUSTRIES (Fire extinguisher) etc.

We Have a Large Range Of Machine Portfolio To Cater To Different Requirements From Different Customers.

Enjoy and contact us for further information!

For Quicker Discussion!

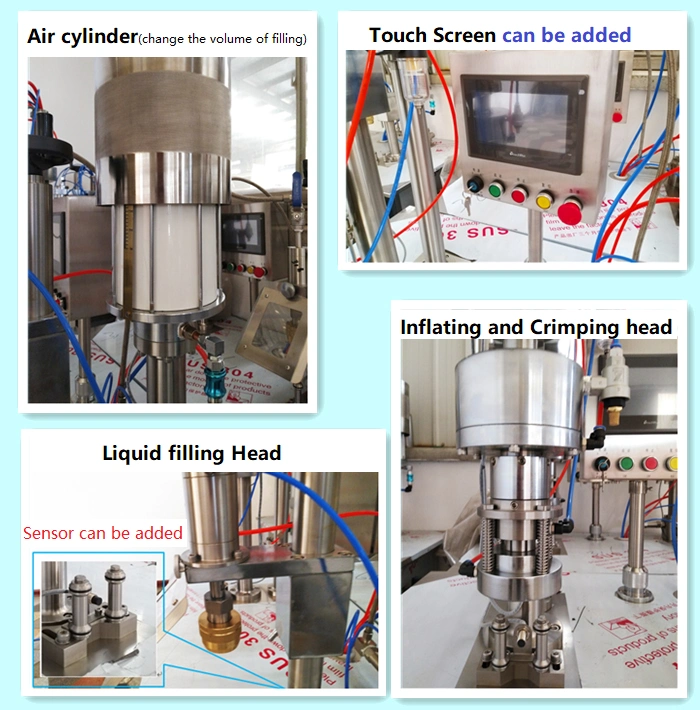

Product descriptionSemi Auto Aerosol Filling Crimping Machine/ Cans Sunscreen Spray Filling MachineThis machine for medical spray can filling machine is specifically designed for bag on vavle aerosol products filling, it is PLC controlled with a frendly touch screen interface, comparing with previous pneumatic control one, this version is improved a lot in efficiency, intelligence, parameters setting, process supvision and trouble shooting. There are two heads seated on the working table, the first head combines the function of vacuumizing, prppellant filling and criimping, more economic propellants are optional for customer such as N2, Co2, Ar or even comperssed air. The second head is aiming to charge the liquid material into bag through the valve, since material is insolated into bag and will not touch propellant, thus this machine is widely used for pharmaceutical, food, cosmetic and other bag on valve products manufacturing. And there is no any limitration about water base, oil base or alcohol based liquid.

Why BoV Packaging is Superior to Traditional AerosolsTo many consumers that enter a supermarket on a daily bases, the quality of an aerosol can may just be another concern that goes overlooked. However, to the industry buyers and manufacturers, an aerosol can can be the difference between an average product and a premium product.

The superior Bag on Valve (BoV) system is developed to not only produce a superior spray dispensing system, but to reduce our ecological footprint through a sustainable packaging process. Compared to traditional aerosol spray technology, BoV aerosols have several benefits for manufacturers, consumers and the environment.

The Standard B.O.V. uses only air or nitrogen to compress the B.O.V. system within the container so it will spray.

| Technical parameter | ||

| Filling capacity | Max.500ml customizable | |

| Filling speed | 400-800can/hour | |

| Filling tolerance | ≤±1% | |

| Applicable valve | 1 inch | |

| Applicable can | height | 60-315mm |

| diameter | 35-70mm | |

| Crimping | depth | 5.0-6.0mm |

| diameter | 26.5-27.5mm | |

| Compressed air consumption | 0.6m3/min at pressure 0.7MPa | |

| Machine size | 1200*650*1670mm | |

| Net weight | 255kg | |

If you need more informations, you can contact me!

FAQ:

Q1:Are you a factory or trading company?

A1:We are a factory specialized in aerosol filling machine . Such as spray print insectcide ect.

Q2:Where is your factory location? How can I visit there?

A2:Our factory is located in Yangzhou,China.You could visit us by air to Yangzhou Airport then we will pick you up to our factory.

Q3:How does your factory do regarding quality control?

A3:Quality is priority People from Meida always attach great importance to quality controlling from the beginning to the end.

We support to inspect machine before shipment . Our factory has gained TUV and ISO authentication.

Q4:What`s the guarantee if we purchase from you?

A4:All the equipment ordered from us will provide one year quarantee from the delivery date. If there is any wearing part be broken within the warranth and isn`t caused by improperly operation then we would offer then new parts for free.

Q5:How about the after service?

A5:There`s no problem we could send our engineer to install or fix the machine locally in due course but customer need to pay the round air tickets cost and arrange the hotel accommodation for our engineer.

Layout design and consultancy is available, contact us!

Our Contact