Rotaray Index Cosmetic Packaging Machinery, Auto Tube Filler Sealer

Description

Basic Info

| Warranty | 1 Year |

| Packaging Type | Tube |

| Weight | 280kg |

| Dimension(L*W*H) | 900*800*1650mm |

| Voltage | 220V/50Hz |

| Machine Material | 304 SUS |

| Filling Accuracy | 99.9% |

| Certification | CE ISO9001 |

| Transport Package | Wrapping Stretch Film |

| Trademark | UTIEN PACK |

| Origin | Zhejiang, China |

| Production Capacity | 100 Piece/Pieces Per Year |

Product Description

Product Description

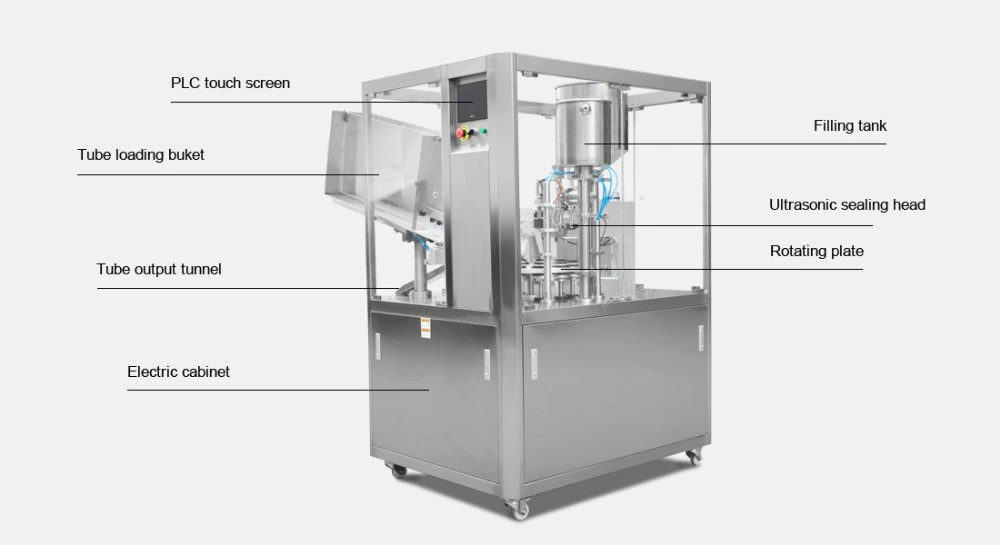

Auto Tube Filling Machine :

It's an automatic machine for plastic tube packing. It can finish the whole process from tube loading, filling, sealing, cutting, and tube output. With ultrasonic technology, it can seal strongly, even when there's a remaining gel/cream stick on the seal seam. No miss sealing, or cream leaking.

It has been widely applied in packing liquid and semi-liquid, custom, and daily commodities, such as glue, toothpaste, facial cream, skin gel, and etc.

Detailed Photos

Details:

More application:

Our Advantages

1) Small: It only occupies a small space, about 1m2.

2) Safety: Once anyone tries to interfere with its production, it will be sensed and stop working immediately.

3) Smart: Easy to control it with PLC screen.

4) Strong sealing: The tube can be firmly sealed even there's a remaining cream stick on the seam.

5) Customize: Shape, pattern, length of the seal, and volume are very much customizable.

6) After sale-service: engineers are available to service overseas.

Product Parameters

Machine structure

Machine details:

High automation

1)Finger touch to control the whole machine;2)Display to show all automatic setting and related data3)Fully auto from tube loading to final outputNo tube, no filler

Piston filler with bottom-up fill and do drip nozzle.No tube, no fill sensorStrong sealing

The ability to strongly seal through product contamination in the seal areaIt's applicable to almost all plastic materialTechnical data:

| Machine Parameters | |

| Capacity | 0-25PCS/min |

| Control | PLC control |

| Frame material | 304 SUS |

| Mold material | 6016 Aluminium |

| Dimensions | 900mm×800mm×1650mm |

| Weight | 400-500kg |

| Tube | |

| Sealing Widths | 3-8(Customizable) |

| Sealing Length | <85mm (Diameter<50mm) |

| Tube length | <200mm |

| Filling volume | <200lm |

| Material | PP |

| Filling product | liquid or half liquid |

| Components | |

| Japan SMC pneumatic parts | French Schneider electrical parts |

| Auto frequency tracker | Taiwan DELTA servo motor and PLC control units |

| Power | |

| Electric | 220V/50Hz |

| Pneumatic | 0.4-0.8 MPa |

The parameter in this sheet is for reference only, some of the data may be different with different case.

After Sales Service

1. WARRANTY1) The whole machine has 12 months warranty exclude wearable parts such as silicone plate, film, heating elements, and so on.2) Special oversea engineering service is not included in the warranty.3) Other items or services require can be negotiated.2. Information1) We offer information about machinery before making a special offer.2) We have multiple after-sale services include online guiding, engineering service, installation & tuning service, and so on.3. Design1) We can customize the machine per customers' tube size and volume.2) We can customize machine function, appearance, and special requests within a reasonable range.

FAQ

Q1:How long does it take to deliver the machine after the order & deposit?

A1:Usually it will take 60 working days to manufacture the machine and make it ready to deliver.

Q2:What do you need to make a specific offer for my product?

A2:To make a special offer we will need the tube size, filling fluidity, and other functions you want to use on this machine. If with other special requests, please also inform us before we make the project.

Q3:Can you offer overseas service?

A3:Yes, if request. But we suggest online problem solving at first. If the problem still shows we can arrange engineer to go to your factory personally to solve the issue.

Company Profile

Prev: Metal Tube Filler and Sealer

Next: Fully Automatic Plastic Tubes Filler and Sealer for Silicone Sealant Tube

Our Contact