Automatic Paste Piston Pump Jam Mayonnaise Ketchup Peanut Butter Chocolate Sauce Food Filling Magnetic Torque Capping Production Line

Description

Basic Info

| Model NO. | PX-CP50 |

| Usage | Outpacking |

| Type | Capping Machine |

| Packaging Material Mechanical Properties | Full Automatic Filling and Sealing Machine |

| Material Type | Paste |

| Driving | Servo Driving |

| HMI | 7.5" Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Capping Head | 1/2 |

| Capping Driving | Servo/Magnetic Torque Motor |

| Transport Package | Non-Fumigation Wooden Case |

| Specification | 1200*900*2200 |

| Trademark | PAIXIE |

| Origin | Shanghai |

| HS Code | 8422303090 |

| Production Capacity | 1000-8000bph |

Product Description

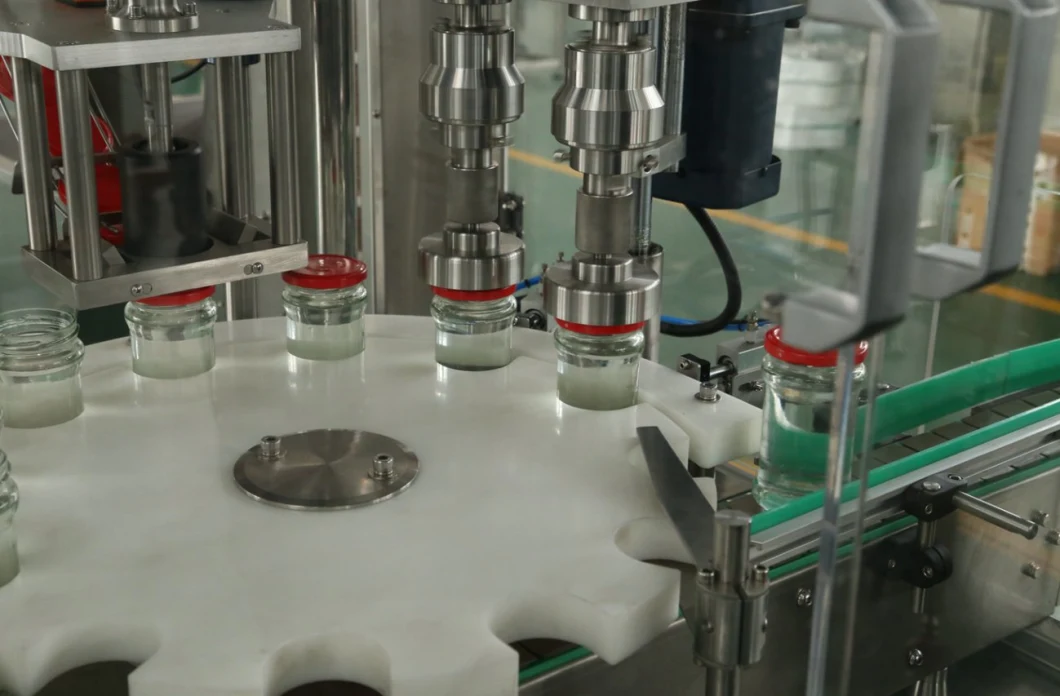

The new PX-CP50 SmartCapper all-in-one capping machine is rated at 40-45 capping per minute to match the filling machine. Rotating "smart turret" star wheel for filling, inserting and capping stations. The star wheel size is customized according to the container size. The vibrator hopper is used to vibrate the lid, it will sort out different specifications, dropper, thread, inner plug, spray head, etc. We use a soundproof cover to eliminate the noise of the vibrator. This keeps decibels low on the production line.The magnetic torque motor is applied to the screw cap, which can adjust the torque freely to prevent the bottle cap from being broken due to excessive torque or too little torque and leaking liquid. Servo motors are also optional.

Parameters| Model | PX-CP80 |

| Capping driving | Servo/Magnetic torque motor |

| Capping head | 1/2 |

| Filling pump | Piston pump |

| Work voltage | 110/220/380V 50/60HZ |

| Air presstion | 0.6MPA |

| Power | 2-3.5KW |

| Driving | Servo motor |

| Direction | Left -right |

| United size | 1200*900*2000mm |

| Weight | 500kg |

| Material | Contacting parts SS304 with Hairline Finish |

| HMI | 7.5" Color Touch Screen Control |

| Protection | Comprehensive Safety Alarm System |

| Speed controller | Variable Speed Controls |

| Detecting system | Vial Detector & Counter |

| Label size | Width : 20-180mmLength : 30-350mm |

| Label color | Transparent /colorful label |

| Label application principle | Rolling labeling /positioning labeling |

| Labeling driving | Servo / steeper system |

| Labeling position | Round /square/top/single /double sides |

1- How can I fill so many formats my bottles with the machine perfectly without complex adjusment?

2- How can I understand your quality? I do not want any kinds bad machine which failed to live up to my investment.

3- How can I know your machine life? It looks always beautiful but only in your room.

4- How can I install such a big long machine by myself? It looks never easy at all.

5- How can I recognize the real difference in chinese market? So many suppliers quoted me every day!!!

6- What should I do if the machine is broken? Who is gonna to help me?

Compared with traditional machinery, PAIXIE smart filler has characters below which are beneficial to each customer operation experience:

1- With servo driving , operator just edit the filling parameter on HMI to realize all kinds products packing.

2- 150mm width SS304 protection frame which equiped with induction switch is able to stop machine whenever operator open the plexiglass door which is good for human protection.

3- PAIXIE'S machines are all equiped with scale rules for diffeferent kinds bottle replacing , which is convenient for date recording and save the time in adjusting.

4- All PAIXIE'S machine are made of SS304+SS316 which avoiding pollution perfectly, protect the quality of customer's product.

5- Machines are delivered as whole which solving the stress of after-sale installation for customer . PAIXIE'S technicians are standing by all time for on-site service

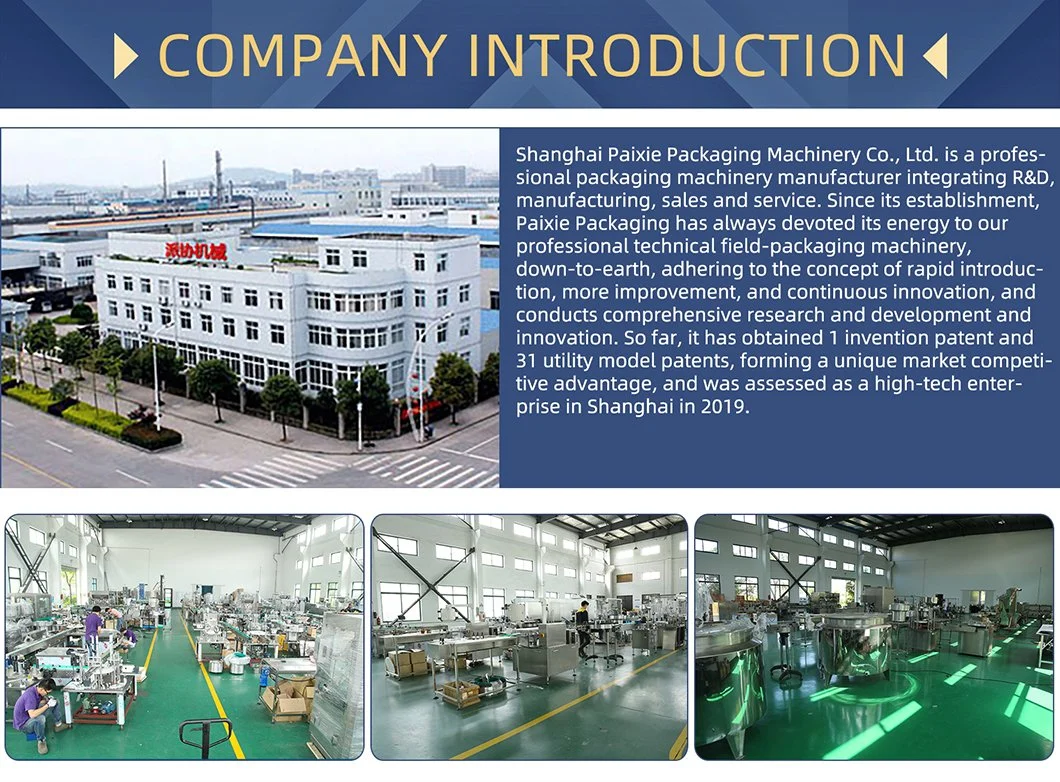

Our Contact