3000bph Automatic Daily Chemical Product Liquid Detergent Gel Alcohol Filling Packing Machine

Description

Basic Info

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Material | SS304 |

| Certificate | CE, ISO, SGS |

| Composition | Filling Machine |

| Processing Material | Oil, Jam, Honey, Alocohol, Detergent |

| Elctric | Siemens, Mitsubishi, etc |

| Bottle Volume | 200ml-5000ml |

| Capacity | 2000bph to 6000bph |

| Exchange Parts | Free Viscous Liquid Filling Machine |

| Transport Package | Wooden Case |

| Specification | 3.2m*1.8m*2.4m |

| Trademark | Proman |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 500machines/Year Liquid Filling Machine |

Product Description

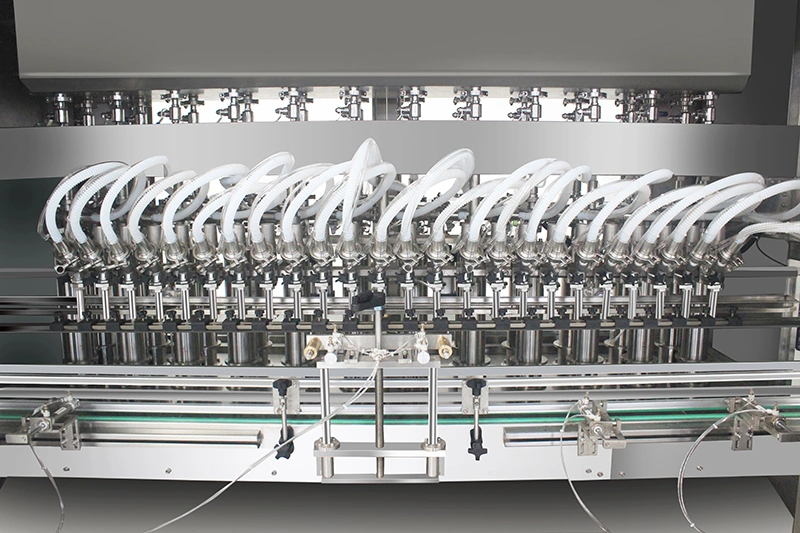

3000bph Automatic Daily Chemical Product Liquid Detergent Gel Alcohol Filling Packing MachineThe daily chemical filling machine is suitable for various viscous and non viscous and corrosive liquid. Daily chemical filling machine series include: laundry detergent filling machine, hand sanitizer filling machine, shampoo filling machine, disinfectant filling machine, alcohol filling machine, etc.The daily chemical filling equipment adopts linear filling, anti-corrosion materials, independent control of electrical cabinets, unique design, superior performance, other in conformity with the concept of international filling machinery and equipment.

This machine is controlled by PLC microcomputer,which is integrated with light,machine,electricity,sensor and pneumatic.

The piston stroke of the injection cylinder is driven by a servor mtor,and the stroke positioning is accurate.When the filling volume is close to the bottle mouth,the speed and pressure are reduced,so as to prevent the material from splashing because of the large momentum.The machine has a high degree of automatic,easy adjustment,when the change of the specification or the correction of measurement can be achieved only by adjusting the display screen.Liquid filling machine

It can be used for filling all kinds of viscous material such as vegetable oil, honey, sanitizer,alcohol,jam,syrup,preparation,suspending agent,oil and daily chemical industry.Liquid filling machine

Features:

1.Accurate Measurement: Adopt servo control system, ensure the piston can always reach constant position

2.Variable Speed Filling: In filling process, when close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollutionLiquid filling machine

3. Convenient Adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment Adopt servo motor to descend

4. Selecting the international famous brand electrical components configuration. Mitsubishi Japan PLC computer, omron photoelectric.The touch screen ensures the quality of its outstanding with long-term performance.

Technical Parameter:

| Model | PM-V4 | PM-V8 | PM-V10 | PM-V12 | PM-V16 |

| Filling head | 6 | 8 | 10 | 12 | 16 |

| Capacity(1L) | 1800B/H | 2400 B/H | 3000 B/H | 3600 B/H | 4800 B/H |

| Power | 1.1KW | 1.5KW | 1.5KW | 2.2KW | 2.5KW |

| Suitable bottle | Diameter:Φ40mm--Φ100mm Height:80mm--280mm | ||||

| Neck diameter | Φ18mm | ||||

| Filling range | 50ml--1000ml | ||||

| Air pressure | 0.6Mpa--0.8Mpa | ||||

| Power supply | 380V; 50HZ Or Customized | ||||

| ITEM | SUPPLIER | Brand | |

| 1 | Touch screen | Taiwan | WEINVEIW |

| 2 | PLC | Japan | Mitsubishi |

| 3 | Photo sensor for bottles | Japan | OPTEX |

| 4 | solenoid valve | Taiwan | SHAKO |

| 5 | Level button | Mexico | JOHNSON CONTROLS |

| 6 | angle seat Valve | Jointed | BURKERT |

| 7 | Diving cylinder | Taiwan | AIRTAC |

| 8 | Power button | France | Schneide |

| 9 | Button | France | Schneide |

| 10 | frequency converter | France | Schneide |

| 11 | Magnetic switch | Taiwan | AIRTAC |

| 12 | oil-water separator | Taiwan | SHAKO |

| 13 | Speed reducer | China | Jiao xing |

| 14 | Relay | Japan | Omron |

| 15 | Servo motor | Japan | Panasonic |

Certifications

1.How to tell us your enquiry? You can contact us by email, phone call, fax, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

2.Where is your factory? Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

3. Do you have any technical supports with your liquid Filling Machine? Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

4.What's your guarantee or the warranty of the quality if we buy your machines? We offer you high quality machines with 1 year guarantee and supply life-long technical support.We Warmly Welcome Customers All Over The World To Our Company If You Have Interests In Our Products. Please Contact Us If You Have Any Problems.

Our Contact